Container inspection

Fill level, cap, label control system with the video camera system Expert.

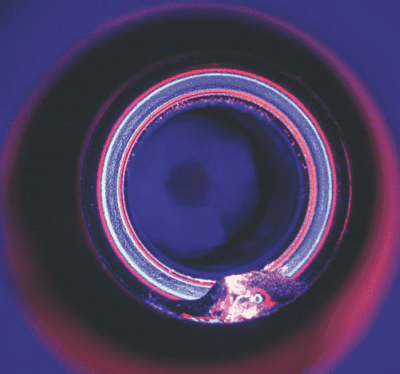

Empty bottle inspection

The completely newly developed UNICHECK V empty bottle inspector meets high performance requirements and optimum ease of operation.

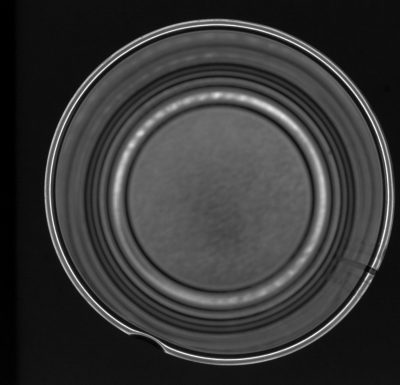

Empty Can Inspector

Empty can control by means of 2-fold video camera system from above

Measuring station with high-resolution CCD cameras and special LED illumination system from above for a

safe and reliable inspection of the can.

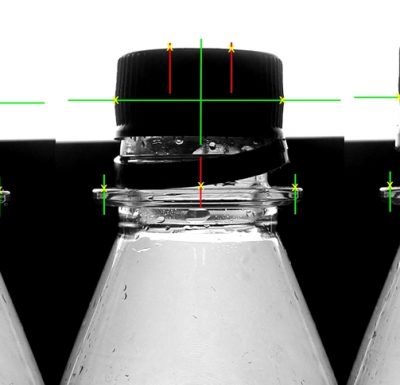

Foreign bottle detection

As they pass along the conveyor belt, the bottles can be accurately identified using sophisticated camera technology in conjunction with special lighting systems.

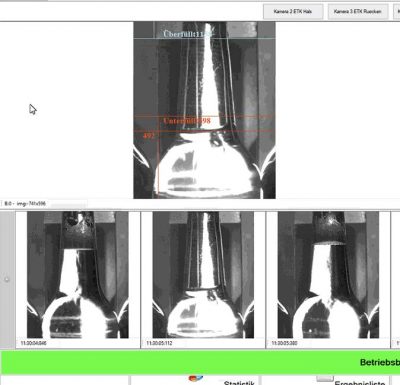

Fill level control

Comprehensive full bottle inspection with video camera for installation after filler or labeler.

Closure control

Safe and reliable inspection of caps/crowns with high-resolution network color camera.

Filler and capper management

Powerful control of filler and capper with System Expert video camera system.

Label and equipment control

Convincing results thanks to LED lighting systems of the System Expert video camera system.

Ironing control

Reliable bottle hanger inspections by means of a full inspection with System Expert video camera system.

Leak test

Detection of leaking containers with Profisonic and non-contact inspection of leaks on containers with Capsonic.

Vacuum control

Reliable monitoring of the vacuum of food cans, jars and bottles with different lid sizes and types.

Residual liquid control

The LC 10 residual liquid detection system safely and reliably checks even small amounts of residual liquid.

With more than 25 years of experience, we are your partner for real detection of container features. Get to know us. We will be happy to advise you on your project: