You are here

- SYSCONA

- Products

- Pallet inspection

- PIA: 360

Pallet control

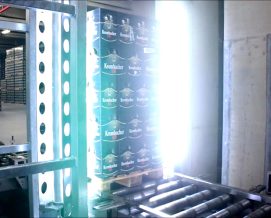

PIA: 360° inspection of loaded pallets

In the full good: Verification of complete, correct and stable loading.

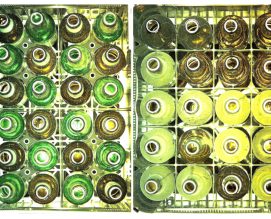

In the back good: Evaluation according to grade purity or degree of mixing. Depending on the degree of mixing, the pallets can either be sent to the warehouse or to a detailed depth testing facility from SYSCONA.

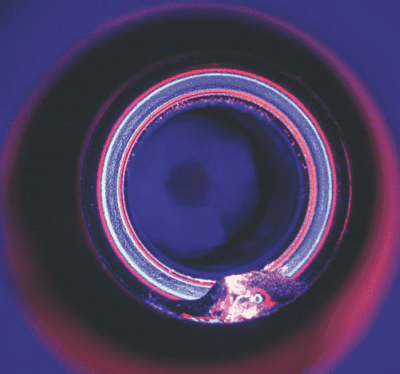

- Plausibility check

- Contour measurement

- Collateral value determination

- Batch tracking for quality improvement of the empties suppliers

- Box logo detection

- Bottle color detection

- Distinction full or empty frame

- Addition of vertical camera from above: Depth inspection of the uppermost layer, as well as statistical extrapolation to the entire pallet.

CONTACT

There for you

Downloads

Details

PIA: 360° inspection of loaded pallets

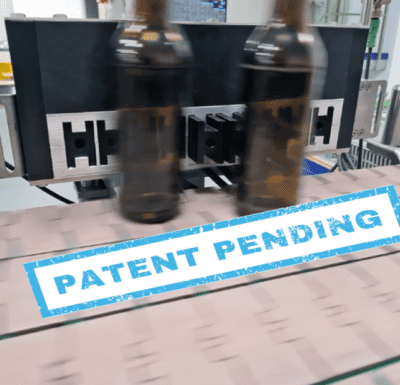

Procedure

Detection is performed on both sides of the pallet in transit by high-resolution color line scan cameras and high-quality LED lighting systems. The entire unit is encapsulated in a solid, mechanical steel structure, therefore optimal protection in case of pallet or box fall.

The illumination is only activated during the pallet pass for image acquisition. An automatic light reference measurement checks the correct function of the lighting system at regular intervals. Fully compatible detection systems for all container types, therefore no mechanical adjustment required.

For use:

- High-performance computing systems

- In-house developed powerful recognition tools

- State-of-the-art Gigabit Ethernet-based color line scan camera technology for brilliant image quality

- Clear multi-touch interface for easy operation

- Visual display of counting, production and diagnostic data

- Differentiated displays according to products and varieties

- Connection to production data acquisition

- Capacity: up to 260 pallets per hour

With more than 25 years of experience, we are your partner for real detection of container features. Get to know us. We will be happy to advise you on your project: