You are here

- SYSCONA

- Products

- Full load control

- Full box control

Full load control

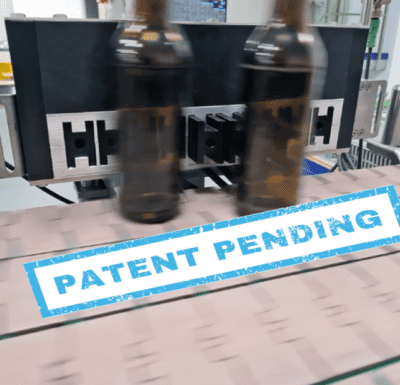

Full box control - Unicept VKK

Unicept VKK stands for a universal concept of a basic system for safe control of the pack in your filling plant. The microprocessor-controlled system checks the contents of crates / cartons for completeness with single or multiple transport lanes arranged next to each other.

A measuring bridge with scanning sensors determines the number of bottles or cans within the compartment rows in free flow. This control system ensures that no incompletely packed crate or carton leaves your filling plant.

CONTACT

There for you

Downloads

- Product brochure

Details

Unicept VKK

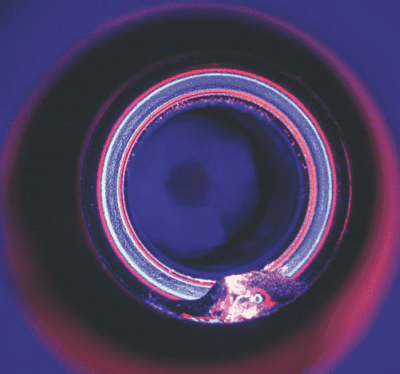

Recognition variants

- optical scanning with light scanners

- In-house developed powerful recognition tools

- acoustic scanning with ultrasound

- inductive scanning with metal proximity switches

- Weight sensing with scale

Equipment

- Solid mechanical design with compact electronics

- Plant design in stainless steel with protection class IP 65

- Measuring bridge to accommodate the scanning systems with height adjustment

- Format change by program selection

- Modern industrial microprocessor control

- Integrated production data acquisition and operating instruction via text display

- BDE connection possible

- direct connection to SYSCONA Sorting systems possible: ProfiPush (a system with pneumatic cylinder) or ProfiGuide (sorting or distribution system for crates and boxes)

- Modification according to customer requirements

With more than 25 years of experience, we are your partner for real detection of container features. Get to know us. We will be happy to advise you on your project: