You are here

- SYSCONA

- Products

- Container inspection

- Filler and capper management

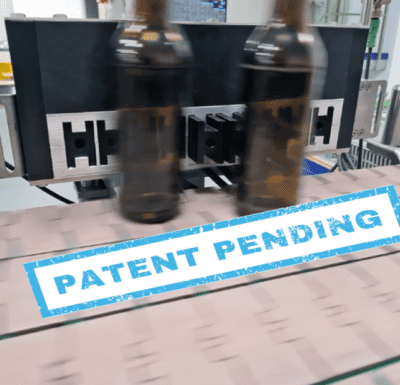

Filler and capper management

with video camera system - System Expert

The Expert system offers the functionality of a comprehensive filler and capper management system.

Filling valve analyzer module

All underfilled or overfilled bottles are assigned to the causing filling valve and corresponding statistics are kept.

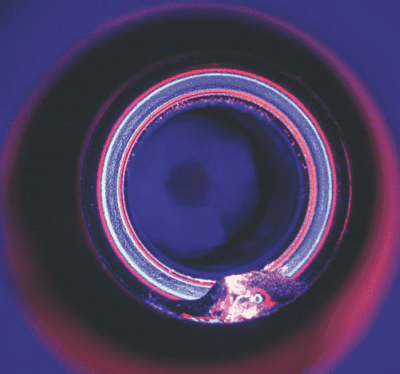

Capper Analyzer Module

All incorrectly capped bottles are assigned to the capping organ that caused them and corresponding statistics are kept.

Fracture bottle analyzer module

For detecting broken bottles in the filler and assigning them to the filling valve that caused them.

Sorting out of neighboring bottles as well as subsequent bottles of the corresponding filling valve via a downstream sorting out system. The number of peripheral bottles and subsequent filler rounds to be sorted out can be freely set.

Sampling module

For targeted removal of sample bottles from filler or capper via a downstream sorting system. The number of bottles and the valve numbers can be freely preselected individually, as a series, or at intervals.

Air bottle rejection

Module for automatically discharging the so-called air bottles between the filler outlet and the capper after the filler has stopped. The air bottles are counted on a separate counting display.

Serial fault - monitoring

Output signal when a serial error occurs to switch off the filler. The number of errors in sequence is freely adjustable.

All data is stored in the internal database and is ready for collection and external processing.

CONTACT

There for you

Downloads

With more than 25 years of experience, we are your partner for real detection of container features. Get to know us. We will be happy to advise you on your project: