You are here

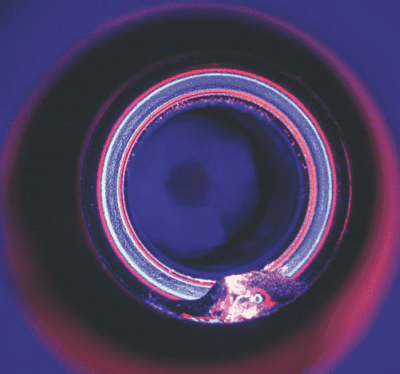

Vessel rejection

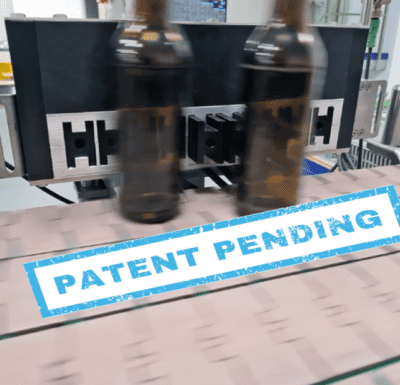

ProfiLane

System for reliable distribution of bottle packs or individual bottles to different discharge conveyors or conveyor lanes. The bottles are forcibly guided in the 1-lane infeed by means of two variable railings. During the changeover to the next discharge lane, the two guardrails are moved in the direction of travel, thus ensuring reliable discharge allocation of the bottle packs.

The two guide rails are adjusted by means of 2 overhead linear motors. The distribution rhythm is freely adjustable; as standard, each discharge lane is fed with 5 bottles, with the two outermost lanes being fed with twice this number.

For example, from left to right: 10 - 5 - 5 - 10 then again from right to left with the same assignment.

CONTACT

There for you

Downloads

- Product brochure

Details

Learn more about ProfiLane

Profilane- reliable distribution

- Line output up to 30,000 bottles per hour

- Bottles with diameter from 30mm to 110mm (fully automatic adjustment)

- The entire distribution is enclosed with transparent sliding safety doors (incl. AZ safety switches and PNOZ safety relays)

- External operation Emergency stop and system stop via a separate control panel mounted up to 15m away

- Plant design: distribution from 1 to up to 4 lanes

- Use of particularly low-maintenance quality components

- lowest qualification requirements for your personnel

- Particularly low-noise, heavy-duty and durable as well as inexpensive

The system structure

The deflection point consists of an electrically guided slideway and therefore offers a simple very space-saving design that can also be mounted over existing conveyor lines.

The deflection system

A super-fast electrically moving and specially shaped railing guides the bottles into the designated lanes. With low line output, any distribution sequence is possible.

With more than 25 years of experience, we are your partner for real detection of container features. Get to know us. We will be happy to advise you on your project: