You are here

- SYSCONA

- Products

- Container inspection

- Leak test

- Capsonic SYSCONA - Tightness control system

Leak test

Capsonic SYSCONA - Tightness control system

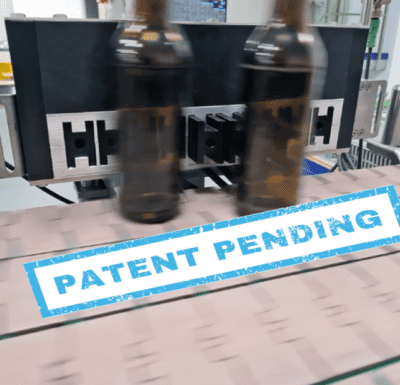

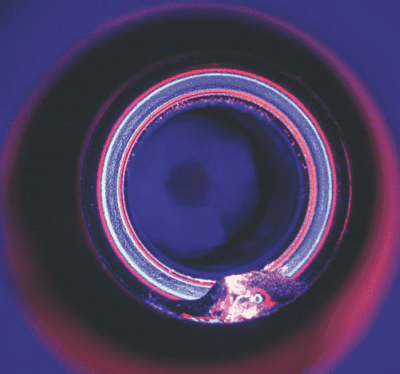

An inspection unit for the non-contact, reliable detection of leaks in glass bottles with metal crown caps, especially with a specific target internal pressure after the filling process, by evaluating vibration characteristics with state-of-the-art electronics and software algorithms.

The special thing:

- Automatic bottle distance compensation

- Compensation of variable influences (temperature, shutter properties, etc.) by dynamic parameter tracking ("adaptive" system)

- Special excitation of the container to increase measurement reliability

- Direct establishment of a reference to the internal pressure of the container as well as adjustment and control of the system with transponder sensor-equipped test containers of the customer

- Ultra-compact dimensions of the station

- Excellent price-performance ratio

This means that sealing, capping or filling faults, including so-called "water pullers", can finally be reliably detected with the lowest possible pseudo-emission. Applications at home and abroad confirm the functionality of the SYSCONA product.

CONTACT

There for you

Downloads

With more than 25 years of experience, we are your partner for real detection of container features. Get to know us. We will be happy to advise you on your project: